These are important tips and hints to apply FN NANO® correctly for the best performance

- Always apply FN NANO ® functional coatings only on a suitable and cohesive substrate. Silicate and acrylic paints are suitable. If you are unsure of the suitability of the substrate, it must be tested by performing a FN NANO® test coating (near a window) on a small piece, leaving it to dry and checking the next day for flaking, cracking, peeling or yellowing. In this case, the old paint must be removed and repainted with a suitable paint.

- An inappropriate substrate is a surface with a strong hydrophobic (water-repellent) effect. FN NANO® is an aqueous suspension. On such hydrophobic surface, it “packs” into balls, and a continuous coating layer can not be made with it. The substrate created with the help of ”paint glue” is not suitable. Such an old coating must be scraped and washed away.

- Care must be taken to ensure that when applying the functional coating FN NANO® does not loosen the substrate. In this case, organic substances can be washed out from the substrate into the coating created by the functional coating. This can manifest itself with discolored spots. However, these spots usually disappear after some time, as a result of the photocatalytic effect. In the interior, it is recommended to always use deep penetration solution in advance and prime the surfaces with quality silicate paint.

- In case FN NANO® functional coatings are applied to walls that are heavily drenched by smoke pollution (such as restaurants, bars, chicken shops, etc.), a primer is required before applying FN NANO®, a deep penetration liquid. Otherwise, dirt deposited inside the plaster and wall can rise into the surface layer. It might therefore turn yellow, and become stained..

- To create, for example, 10 m2 interior of photoactive surface, it is necessary to apply 1 liter to this area evenly — in three layers (undiluted and perfectly mixed!!!) FN NANO® functional coating. This quantity is optimal to ensure sufficient strength of the photoactive layer, which will be created by applying the paint. The uniformity of applying the material and the thickness of the formed layer are a necessary condition for ensuring its proper functionality. In the event of non-compliance with this application principle and the formation of a too thin, weak layer (for example, through unequal treatment or dilution of the paint with water), the photocatalytic effect may also act on the substrate, this is manifested by his yellowing and odor.

- The individual layers must be applied so that the following layer is applied to well applied preceding layer. Apply the third layer only after the previous two layers have completely dried.

- If the goal is to create a surface that allows easy removal of graffiti, it is necessary to apply 6 or more coats of functional paint FN NANO ® . Graffiti removal is easy. The optimal procedure is to first spray the surface treated with FN NANO ® with a stream of water and then clean the surface and the graffiti with a coarse brush and spray with pressurized water. 6 and more layers of FN2 NANO® functional coating must be reapplied to the surface where the removal of graffiti was carried out.

- FN NANO® functional coating can be applied using a brush, roller or spray.

- The spraying method ensures uniform application of the material, rapid work progress and lower consumption on the solid surface. Spray with a device that creates the finest possible droplets. Professional or semi-professional spray guns of the HVLP type with nozzles designed for paint work have proven suitable for interior design. For applications of large areas in the exterior, it is also possible to use airless high-pressure spray devices with a coating mixer. For the application of FN NANO® coatings, we do not recommend mechanical nebulizers and sprinklers because they do not create even droplets.

- Spray as evenly as possible. In this way, apply the formed aerosol “mist” evenly and in a thin layer on the target surface. Take care not to create wet shiny places when spraying on the substrate. They are a symptom of the formation of too large a layer. The paint on them can trickle down, there may also be a dents of the substrate, or a cracking.

- Verified semi-professional instruments: Wagner W550, Gracco and others. Use of other types of equipment is possible.

- For roller application, low-profile paint rollers are mostly suitable in the interior. For applications on a rough surface (for example, facade) we recommend rollers with a higher hair or a combination of a roller and brush (if there are many rough surfaces). The application must be carried out with an unruffled roller at a brisk pace so that, especially for more soaring substrates, they do not sweep and excessive consumption of the material. The use of a brush is suitable in cases where it is not possible to use spraying or applying with a roller. Always follow this to create a continuous layer.

- Areas not treated with FN NANO® functional coating and objects in rooms where the paint is applied must be thoroughly covered with a protective sheets (dropcloth). Sections of protective sheets are recommended to overlay and fasten with a painter’s “masking” tape.

- In order to ensure the functionality of the photoactive layer, it is necessary that the areas treated with the FN NANO® functional coating experience enough daylight or ensure sufficient artificial source of ultraviolet (UVA) light (best are lamps or bulbs in the range 350 — 375 nm, optimal wavelength for photoactivation is 365 nm). The minimum power of the source in relation to the enhanced area shall be governed for UV-A fluorescent lamps according to rule 1W of the electrical power supply per 1m2 of the saturated area. The minimum intensity of UV-A radiation to ensure the functionality of the photocatalytic area is 0.2W/1m.

APPLICATION VIDEOS

How to apply FN® with a roller

How to correctly apply FN NANO®Wood to dry treated wood

How to properly clean the facade and apply FN NANO® coatings

Techniques for applying FN NANO® functional coatings to facades

The importance of UVA light for interior activation of the FN NANO® surface

In order to ensure the functionality of the created photoactive layer, it is necessary that the treated areas The FN NANO ® functional coating caused daylight or illumination with a soft source of ultraviolet (UVA) light. The recommended intensity is 20 μW / cm² (0.2W / 1m 2 ). For much polluted spaces, it is recommended to increase this intensity approximately 5x. At stated, UVA resources are completely harmless to the health of both humans and animal darlings. For clarification: in the winter months in cloudy skies, the intensity of UV radiation in daylight is 10x higher than the recommended indoors saturation values of our coatings.

The optimal wavelength for photoactivation is 365 nm.

Outside (in the exterior), throughout the year (including the winter months) in daylight (even in the shade), contains such an amount of UV radiation that ensures full photocatalytic cleaning performance of the paint layer FN NANO®.

Inside buildings, in interiors, however, the situation is different. There is no daylight in a number of spaces, and where there are windows, very little ultraviolet radiation penetrates through their glass. If we want to ensure good functionality of photocatalytic coating even in the interior where there is not enough UV radiation from daylight, it is necessary that the painted surface is saturated with ultraviolet light with a wavelength of 365 nm (UVA).

While ultraviolet light with shorter wavelengths activates the photocatalytic process too, it can cause harm to health when it is used. Therefore, the use of UV resources referred to as UVB and UVC is recommended only in specialized workplaces such as biolaboratories, hospitals, etc.

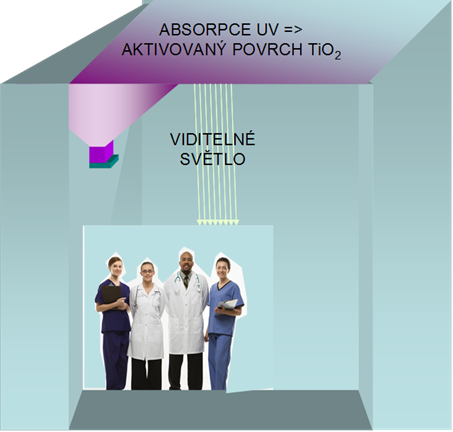

We always install the light source so that the light is directed at the photocatalytic surface created by the FN NANO® coating:

Scheme of possible illumination of the ceiling of the room with a source of UV light:

The minimum power of the source in relation to the enhanced area shall be governed for UVA fluorescent lamps according to rule 1W of the electrical power supply per 1m of the saturated area. The minimum intensity of UV-A radiation to ensure the functionality of the photocatalytic area is 0.2W/1m. The higher the intensity of UV radiation impacting the photocatalytic surface, the better its surface is able to break down harmful substances in the air and dispose of microorganisms. Follow the instructions of the manufacturers of light sources, and when using UVA lamps with high power, the light was directed to surfaces painted with FN NANO® and did not shine directly into people’s eyes.

UVA lights and bulbs can be purchased with normal processes (on-line, mainly). Most commonly used are actinic UVA fluorescent lamps emitting blue-white light or “Disco light” (Black Light) fluorescent lamps emitting UVA radiation in the invisible part of the spectrum. In addition to fluorescent lamps, some types of special lamps and LEDs that produce UVA radiation of the recommended 365 nm wavelength can be used.

Ultraviolet light s with UVA 365 nm

![]()

Příklady nasvícení UVA v interiérech:

For effective lighting, it is important to pay attention to the selection of a suitable luminaire in which a fluorescent lamp or other UVA light source is placed. When choosing lights, prefer aluminum reflectors. *Note aluminum foils reflect UV radiation while steel, enamel and other materials absorb it. This deprives us of the required light output.

How to apply FN Aqua

FN® Aqua is an aqueous preparation of health and harmless inert minerals. It serves to reduce the consumption of chemicals in the maintenance of pool water and chemical-free maintenance of ponds.

The substances contained in the suspension by physical and mechanical influences effectively prevent the overgrowth of undesirable microorganisms. They make it possible to reduce the amount of chemicals used to maintain water and maintain its quality. Daylight is a condition for proper function and we recommend using it together with a UV lamp, wherever possible.

The preparation reduces the overgrowth of microorganisms by using the following

mechanisms:

- coating microorganisms with inorganic film,

- cutting off nutrients

- UV absorption prevents photosynthesis.

- The light-activated particles of photoactive titanium dioxide exert a huge energy of released electrons and electron holes on the surface of bacteria, where they rupture the molecules of organic matter that make up their cell wall. This will cause it to rupture and subsequently disappear.

RECOMMENDATIONS FOR USE:

OUTDOOR OPEN SWIMMING POOLS:

It is suitable for outdoor outdoor pools or pools with a fine sand filtration system or filter cartridge containing zeolites (eg ZELBRITE) and equipped with recirculation with a UVC lamp (hard antibacterial radiation).

It is not suitable for public swimming pools and swimming pools without perfect and regular maintenance.

ROOFED SWIMMING POOLS:

It is suitable for roofed swimming pools with fine sand filtration or a filter cartridge containing zeolites (eg ZELBRITE) and a UV lamp, which is part of the filtration system and is used regularly. The possibility to open the swimming pool in summer for direct sunlight is an advantage.

GARDEN PONDs:

Very suitable for maintenance of garden ponds.

FN NANO® AQUA can be used in parallel with chemicals.

APPLICATION PROCEDURE AND PRINCIPLES:

Consumption and dosage:

FN NANO® AQUA (hereinafter FNA) is supplied as a concentrated suspension in plastic bottles with a volume of 0.25, 0.5, one or five liters.

For continuous maintenance in order to reduce the amount of chemicals for pool water maintenance, 0.1 liter of FNA concentrate is used per 10 m3 of pool water, ie 50 ml of FNA concentrate.

The application of FNA is carried out in the prescribed amount regularly in the interval of 7-14 days according to the water level in the pool and the intensity of use.

Preparation of the suspension and its application to water:

The FNA is applied to the pool diluted and freshly blended.

Preparation of diluted FNA:

Shake the FNA perfectly (1 min.) In the original bottle and pour the required amount into a larger container, where it is perfectly mixed with a bar mixer with at least 0.5 liters of water. Mix for at least 3 minutes.

2. FNA dilution:

Gradually and evenly add the required amount of water to the mixed FNA and continue mixing. The recommended mixing time is at least 8 minutes. and follow the breaks recommended by the mixer manufacturer. Note The better we mix, the better the function and the lower the consumption.

Adherence to the suspension preparation procedure is important to achieve a perfect distribution of its mineral components in the water, and thus to ensure good functionality of the product!

APPLICATION VIDEOS:

After winter cleaning of the pool

CONTINUOUS MAINTENANCE OF POOL WATER:

“WINTERIZING” THE POOL WITH FN NANO®AQUA

SELF-CLEANING POOL WALLS (suitable only for in-ground pools with solid walls):

HOW TO PERFORM CHEMICAL-FREE MAINTENANCE OF A NATUAL POND